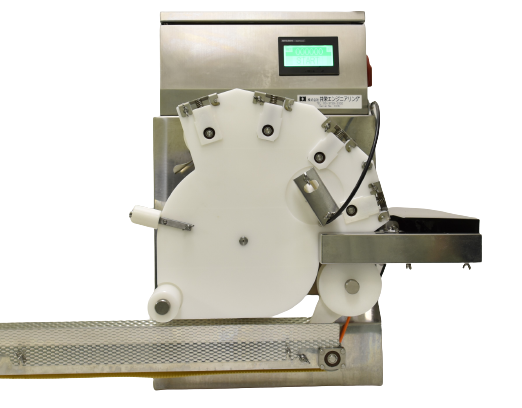

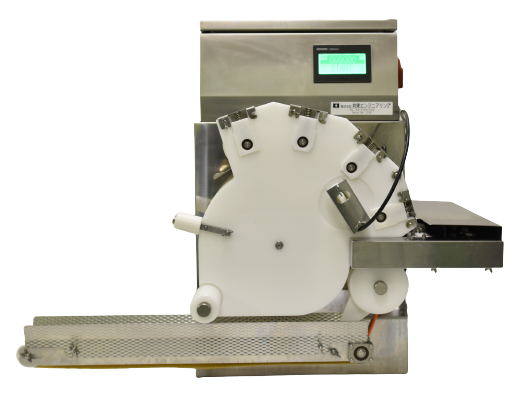

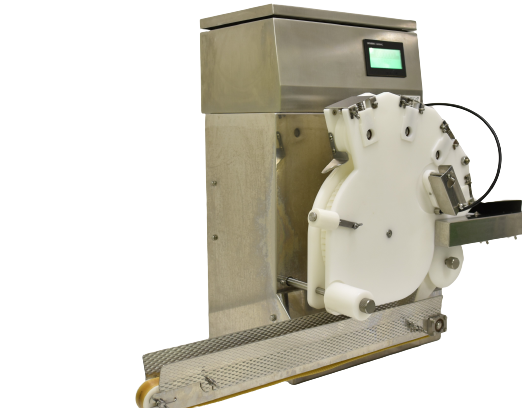

Our engineers have developed a new machine, the "Hog Casing Sausage Cutter KKS-631", which offers improved performance and ease of use. We are excited to introduce this product to our customers.The KKS-631 is a specialized machine designed for the precise, hygienic, fast, and automated removal of curved sausage links in industrial food processing. Specifically designed for hog casing sausage, winners, and frankfurters with a strong "curve," this machine offers unparalleled efficiency and accuracy. The conveyor speed can be adjusted to control the amount of product supplied to the subsequent line, allowing for optimal customization.

In combination with the KKS-850 skewer, this machine provides a cost-efficient and reliable system for the removal and skewering of twisted parts. Together, these machines offer an integrated solution for automated sausage processing that ensures consistent quality and productivity.